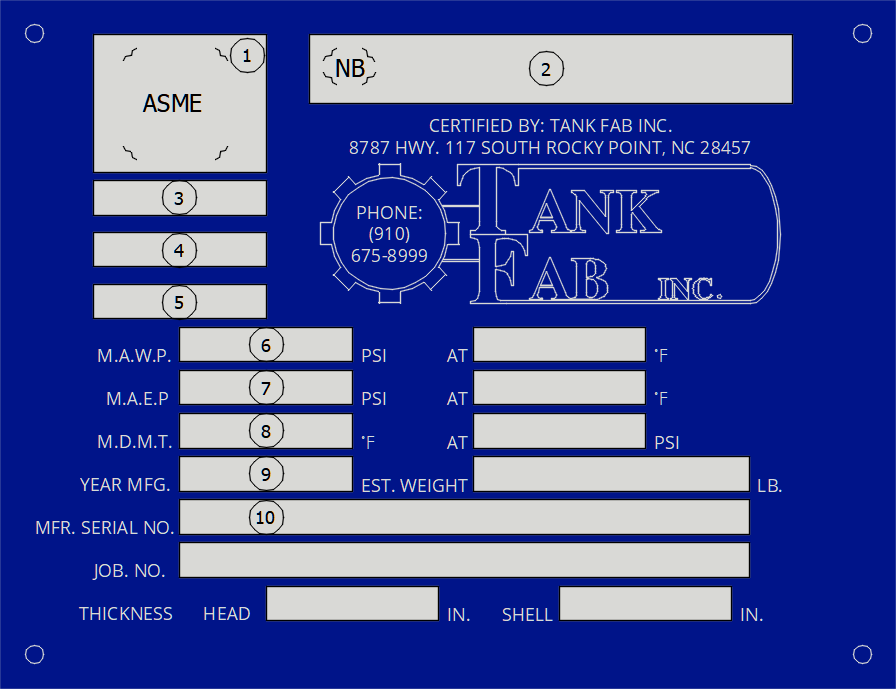

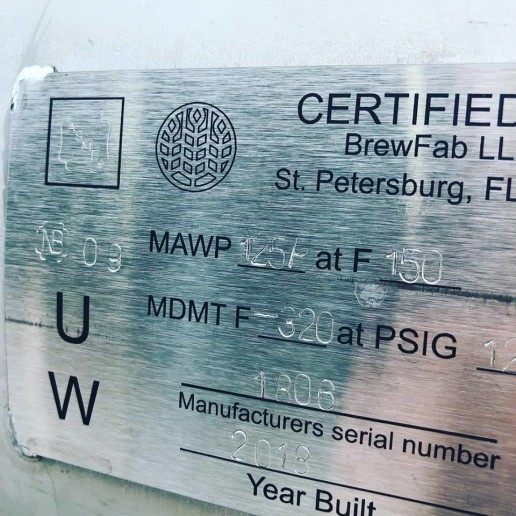

The manufacturer serial number – item 10 on the nameplate example.The year the pressure vessel was manufactured – item 9 on the nameplate example above.The National Board number – item number 2 on the nameplate example above.The name of the pressure vessel’s manufacturer, listed behind the wording “certified by:” on the nameplate.You’ll need the following information off of the nameplate when placing an order for this report: If you ever lose this document, you can contact the National Board, and, for a small fee, receive a copy of the manufacturer’s data report. Without the data report and the nameplate, most inspectors will not allow the operation of the pressure vessel within their jurisdiction. The document, along with the nameplate, is proof to all federal, state, and local regulators that your pressure vessel meets the requirements of the ASME Code. This is a great benefit to you, as the pressure vessel owner. If the pressure vessel manufacturer chooses to register the vessel’s manufacturer’s data report with the National Board, a unique number is assigned to the pressure vessel and is displayed here. This location on your pressure vessel nameplate is reserved for the display of its National Board number.

#National board number pressure vessel code#

Once the pressure vessel passes its final inspection, the ASME Code mark is stamped onto the nameplate, proving the vessel was built in accordance with this standard.

Part 1 : Installation - This Part provides information and guidance to ensure all types of pressure-retaining items are installed and function properly.

It is divided into four volumes or parts. The National Board of Boiler and Pressure Vessel Inspectors Codebook, popularly known as the NBIC (National Boiler Inspection Code), has a long history of setting jurisdictional standards in North America and, it is the only standard recognized worldwide for in-service inspection, repairs and alterations of boilers and pressure vessels.

0 kommentar(er)

0 kommentar(er)